Earth Moving & Construction Equipments

We supply oil-free or lubricated piston compressors, with water-cooled cylinders. Our compressors are complete with electric motor, air or water heat exchangers, instrumentation, electrical panel, filters and are mounted on skids; in other words, ready to use.

Our compressors can compress all types of gas: inert, oxidising, toxic, explosive and corrosive.

1. Compressors for Refinery: code 177

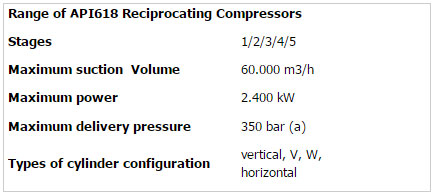

Reciprocating compressors manufactured in full compliance with API618 standard fifth edition and IGC doc 10/06/E. Package design according to international engineering and manufacturing standards. Special attention is given to minimize installation activities on site. Thousands of compressors are in operational all over the world.

2. High Pressure Air compressors: code 175

Customization of packages is done according to the customer’s specifications. Selection of specific materials insures the purity & quality of the compressed air.

3. Instrument & Service Air compressors: code172

The compressors are highly energy efficient compared to screw compressor

4. Boil-Off Gas Compressor

Thanks to its specific know-how applied in the selection of critical components, including piston rings and rider rings, and of valves in special steel alloy, SIAD Machine Impianti compressors assure more reliability and security while minimizing maintenance operations.SIAD Machine Impianti is proud to offer highly efficient and reliable two stages Boil-off Gas compressors for LNG to better meet the needs of LNG services.SIAD Machine Impianti offers cryogenic gas reciprocating compressors operating with an inlet temperature up to –160 °C, skid-mounted, to facilitate installation and start-up, and a specially designed to be installed in places with limited space.

5. Oxygen Gas Compressor: code 156

SIAD Machine Impianti’s oxygen compressor offering consists of a full range of highly reliable oil-free piston compressors with a variety of specifications for different application requirements. Our compressors are skid-mounted to facilitate installation, and have a compact layout and linear design which simplifies maintenance and commissioning. SIAD Machine Impianti is a member of EIGA (the European Gas Association), the body in charge of establishing oxygen compressor safety standards. Furthermore, our fabrication processes use oxygen-specific components, and we have an Oxygen Zone facility exclusively dedicated to the assembly of oxygen compressors in zero contamination conditions. Compliant with the IGC standard, SIAD Machine Impianti’s oxygen compressors are backed up by our Aftersales Service, which is available 7 days a week.

6. CO2 Gas compressor: code124

Fifty years of experience in the compression of wet carbon dioxide with hundreds of compressors in operation throughout the world.

7. Offshore Compressors: code 188

Compressors are compact ergonomics for confined spaces. Package designed to minimize the maintenance frequency which gives greater return on investment.

8. Hydrogen Gas Compressors: code 174

Piston rods specifically treated and with double distance piece to prevent the steel from becoming brittle due to the hydrogen.

9. Nitrogen Gas Compressors: code 179

Over fifty years of experience in manufacturing Nitrogen compressor. Maximum operating pressure can be 350 bars. Attention is given in selecting suitable materials in case of bone dry nitrogen compression.

10. Helium Gas compressors: code180

Worldwide experienced in the treatment of Nobel Gases like Helium for cylinder filling purposes

11. Hydrogen PSA plant: code 173

API618 Reciprocating compressors manufactured to suite the Feed Gas, Tail Gas & product Hydrogen for PSA hydrogen production plant. We have excellent flexibility in adapting to different process conditions.

12. Nitrogen PSA plant : code 178

Experience in all industries in which PSA or Membrane plants are used for the production of Nitrogen.

13. Compressors for Polypropylene Plants: code176

All types of reciprocating compressors available for use in Polypropylene plants.

14. Vent Gas Recovery compressors: code 158

Our experience is the basis for our compressors for mixtures of Hydrogen, Hydrochloric Acid, Di/Tri- Chlorosilane and silicon tetrachloride. Have experience in manufacturing Vent Gas Recovery compressors in Solar Grade Polysilicon Production Plant using CVD Technology.